Product Series

Industrial Double Stack Dryer Manufacturers

Kingstar Energy-Saving Dryers feature a 10-inch full-color high-definition touchscreen design and incorporate a leading intelligent drying system. They can store up to 99 drying programs, all of which are editable to accommodate different types of garments and linens based on specific requirements.

Utilizing a dual-door opening system (top and bottom access) with a generous door diameter of 1 meter, loading and unloading towels becomes exceptionally time-saving and effortless. The dryer drum is constructed entirely from 304 stainless steel. Its volumetric capacity follows a 1:20 load ratio design principle. This large-capacity drum significantly enhances the drying efficiency for both clothing and linens.

Kingstar dryers implement multiple energy-saving technologies, ensuring not only reduced energy consumption but also superior operational efficiency. They incorporate high-power heating elements combined with an added insulation layer around the outer drum. This facilitates rapid temperature rise, minimizes heat loss during operation, reduces overall energy expenditure, and effectively maintains optimal temperature within the drum – all contributing to heightened drying efficiency. Furthermore, the excellent thermal insulation safeguards electrical components and extends the service life of parts. The axial air intake design ensures hot air travels a longer path through the drum interior, maximizing heat utilization efficiency. Advanced intelligent humidity control technology precisely manages drying duration, effectively preventing both under-drying and over-drying scenarios. This results in fluffy, soft towels and garments while simultaneously lowering the dryer’s energy consumption.

All components and spare parts used in Kingstar Industrial Dryers are of premium quality, guaranteeing outstanding operational stability and extended equipment lifespan. Customers can choose from three distinct heating methods to suit their infrastructure: steam heating, electric heating, or gas heating.

Kingstar Industrial Dryers are available in a comprehensive range of capacities from 40kg to 120kg. Additionally, a 100kg front-tilting model is offered, featuring a forward-tilting discharge mechanism for even easier unloading. Kingstar Industrial Dryers are extensively utilized across diverse facilities including laundries, central laundry plants, and industrial & mining enterprises. They have received unanimous customer praise for their high efficiency, significant energy savings, and exceptionally user-friendly operation.

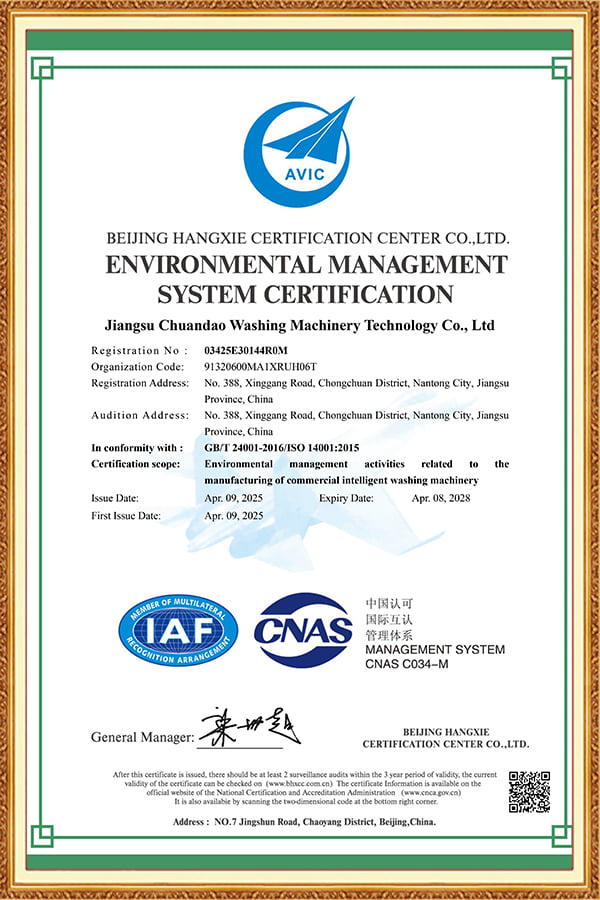

Honor & Qualification

Choose comes from trust, and cooperation

comes from honesty.

About us

Craftsman spirit, excellence, quality products are the bridge to the world!

Kingstar brand is the crown jewel of CLM in the commercial laundry industry. For over 20 years, we carefully selected and updated our material suppliers and technology. We aim to be the best in the industry internationally and offer more to clients who rely on us for their business.

We hold the leading status in the laundry manufacturing industry in China after 25+ years of experience.

NEWS

2.The Role of Washer and Dryer Efficiency in Environmental Sustainability

3.The Future of Double Stack Dryers: Innovation and Market Trends

English

English русский

русский Español

Español Deutsch

Deutsch